PACKAGING | HANDLING | STORAGE

Packaging :-

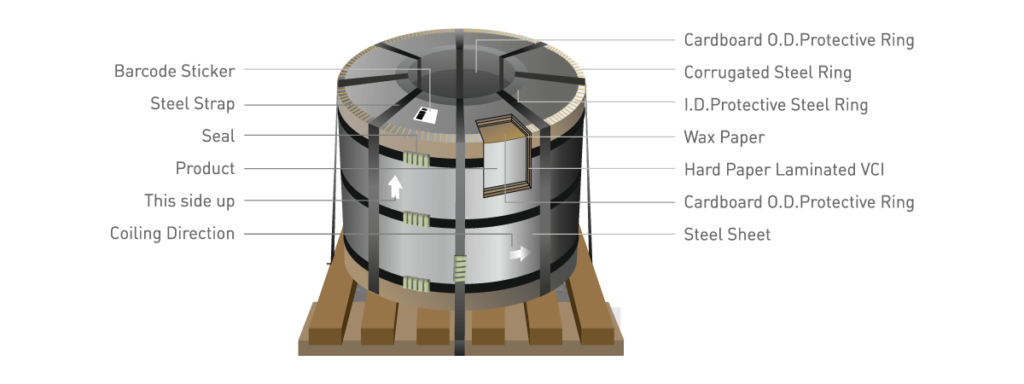

TRIMURTI ENGIMETAL & STEEL WORKS PVT LTD (TEPL) offers its products with effective packaging as per customer requirements and in compliance with international norms. Emphasis is placed to ensure durability, prevention of any damage during transportation and better storage. TEPL with its years of experience and regular benchmarking with various national and international companies, endeavours to improvise packaging in accordance with changing customer needs.

TEPL has a stringent procedure for evaluating the competency level of suppliers for packaging material. Material quality is maintained to high standards and verified before offering for use.

The packing requirements for export and domestic markets are different. However, the type of packaging is determined in consideration of the following points:

- Customer needs

- Duration of transportation

- Environmental conditions during transit

- Handling at customer's premises

- Storage practices

- International regulation on package material

Eye To Sky Packing

Eye To Sky Packing

Slit - Master Coil Packing

Sheet Packing

Packaging :-

- During transportation, it is recommended to put the rubber pad on the skid to avoid blocking issues; this will also help to protect it from white rust due to moisture

- Handle it with care and do not pile it up higher than two levels

- In the event of contamination, wash it with the solvent

- If the design layer peels off, follow the instruction manual provided by TEPL

Marking :-

Marking, in concept, leads to product accountability and verification at the time of production, transportation and delivery. Considering the vast product range at TEPL, labelling practices ensure a foolproof identification and traceability.

Mark of Ingenuity - Non-Erasable Liner Marking

Storage :-

- Packets/Sheet should be stored in covered, clean and ventilated building and be stacked neatly clear off the ground at an angle to the ground, over a base pallet to provide drainage.

- Avoid storang in open, Packets must be covered with water proof covering to protect from moisture, rain and foreign particles. Adequate air gap should be provided.

- Water / moisture should not be allowed to stagnate on surface, or in between layers. This can damage the coating and cause corrosion.

- If sheet get wet, sheet should be separated without any delay and be wiped cleaned and dry before re-stacking.

- Sheet above 3 mtr. length should be provided multiple center support/wedge blocks to prevents sagging / deformation.

- In case of storage for over a longer period, material should be inspected periodically.

- If the original packing is removed then adequate markings etc, should be maintained for easy identification and retrieval and defective / unsatisfactory sheets observed should be separated out with the identification or packet no. for inspection by supplier representative.

- Sheets lefts unused at end of the day should be properly secured covered for protection.

- Exposed sheets lying in open should be protected against dust, sand, grit cement / lime dust, water etc Sheets should be clean before installation.